CASE STUDY

Harbor Steel Piles Protected from Corrosion and Icy Environment with SeaShield™ Series 500 & 2000HD

Subsea & Splash Zone Coatings

Project Data

| Location | Superior, WI |

| Completion | 2010 |

| Project Type | Harbor Steel Pile Protection |

| Products Used | SeaShield™ Series 500 & 2000FD |

| Contractor or Applied By | N/A |

Project Details

The SeaShield Series 500 and Series 2000FD Systems were selected and installed in the Duluth-Superior Harbor to provide corrosion protection of the steel piles. Over the years the Duluth-Superior Harbor has experienced corrosion problems with many of the dock structures due to the bacteria in the water. The environment can be quite aggressive during the winter months as there is a large ice buildup that provides impact damage, as well as extreme thermal expansion and contraction forces.The SeaShield Series 500 and Series 2000FD Systems were used to protect H-piles and cylindrical piles to help solve the ongoing corrosion problem.

The SeaShield Series 500 was used to protect the steel H-piles. The system includes a custom fabricated Fiber-Form Jacket and SeaShield 550 Epoxy Grout. The Fiber-Forms were fabricated in two half shells to the shape of the existing H-pile to allow for a 1″ (25 mm) annulus space between the jacket and pile. The Fiber-Forms were installed and secured with self tapping screws and temporary nylon straps. The 1″ (25 mm) annulus space was adjusted with plastic offset screws. The SeaShield 550 resin, hardener and aggregate were mixed and then poured through a pneumatic vibratory funnel into the top of the jacket.

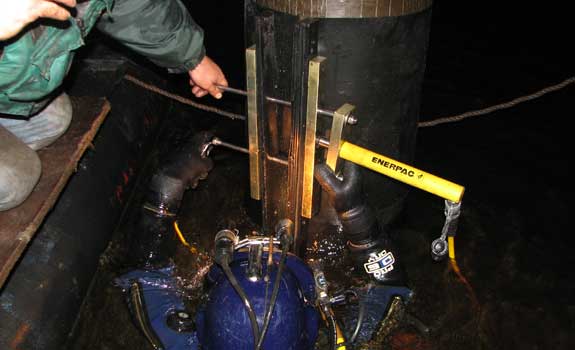

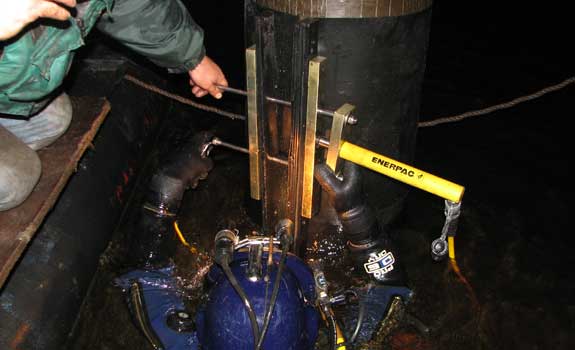

The SeaShield Series 2000FD was used to protect the cylindrical piles. The system includes a Denso Marine Piling Tape and a custom engineered HDPE outercover. The Denso Marine Piling Tape was applied above and below water with a 55% overlap. The outercover was then installed and secured with 316 stainless steel bolts using Denso’s proprietary tensioning bars and hydraulic equipment. The SeaShield Series 500 and 2000FD Systems have been inspected after one year of severe winter ice buildup with no damage. The systems have provided a long-term solution for this aggressive environment.

Denso manufactures a full line of SeaShield Pile Protection Systems and pipeline coatings that are considered the choice by owners, engineers and dive contractors around the world.

Installation of the two Fiber-Form half shells around a steel h-pile.

Installation of HDPE jacket and hydraulic tensioning system.

SeaShield™ Series 2000HD protecting a steel pile during winter ice build up.

Installation of the two Fiber-Form half shells around a steel h-pile.

Installation of HDPE jacket and hydraulic tensioning system.